- HOME

-

PRODUCT

Gas-fired(oil-fired) boilers

WNS gas-fired (oil-fired) skid-mounted steam boiler WNS Fire tube boiler/ Gas-Oil Fired Steam Boiler/Lpg Gas Boiler WNS Series Gas/Oil Fired Hot Water Boiler SZS Series Gas/Oil Fired Steam Boiler

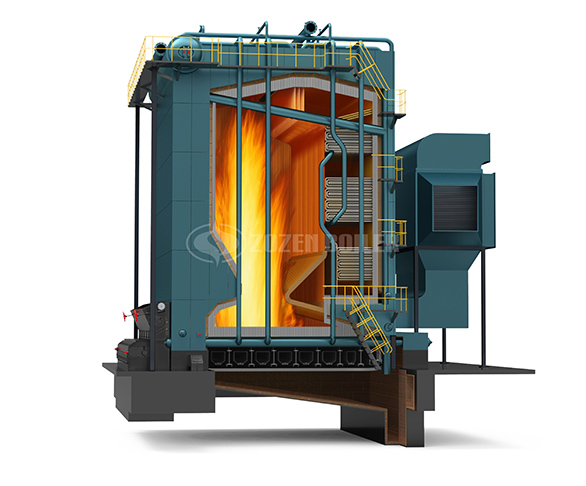

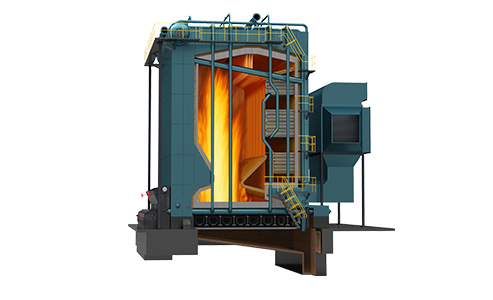

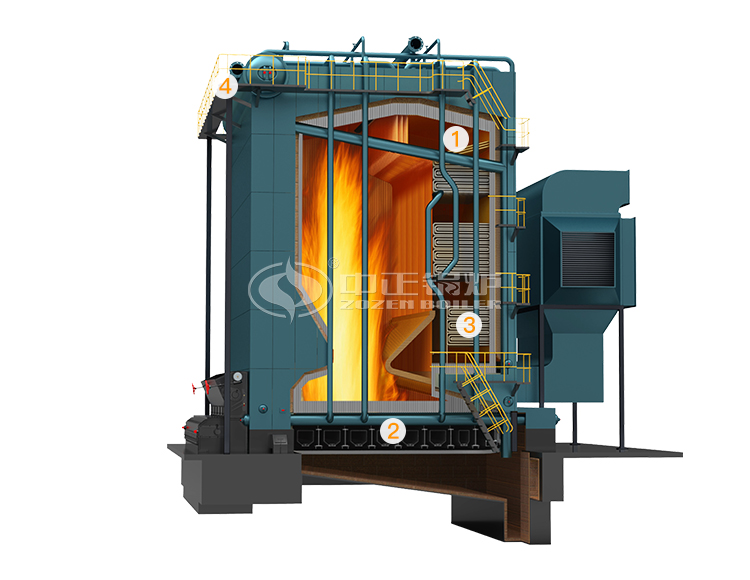

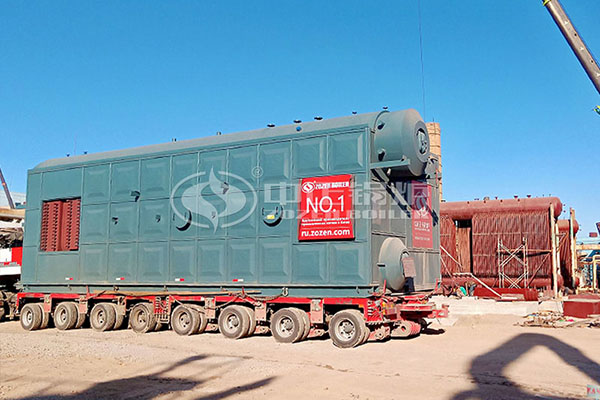

Coal-fired boilers

DZL Series Coal Fired Steam Boiler DZL Series Coal Fired Hot Water Boiler SZL Series Coal Fired Steam Boiler SZL Series Coal Fired Hot water Boiler - APPLICATION

- CASE

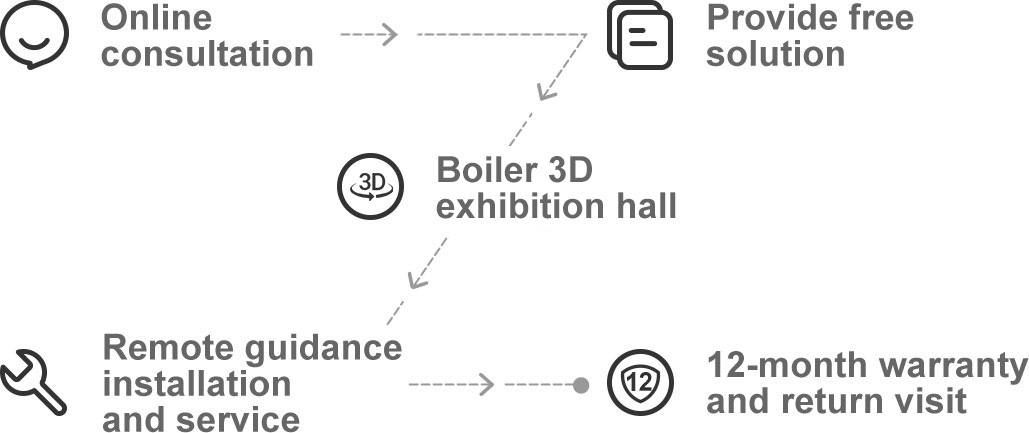

- SERVICE

- NEWS

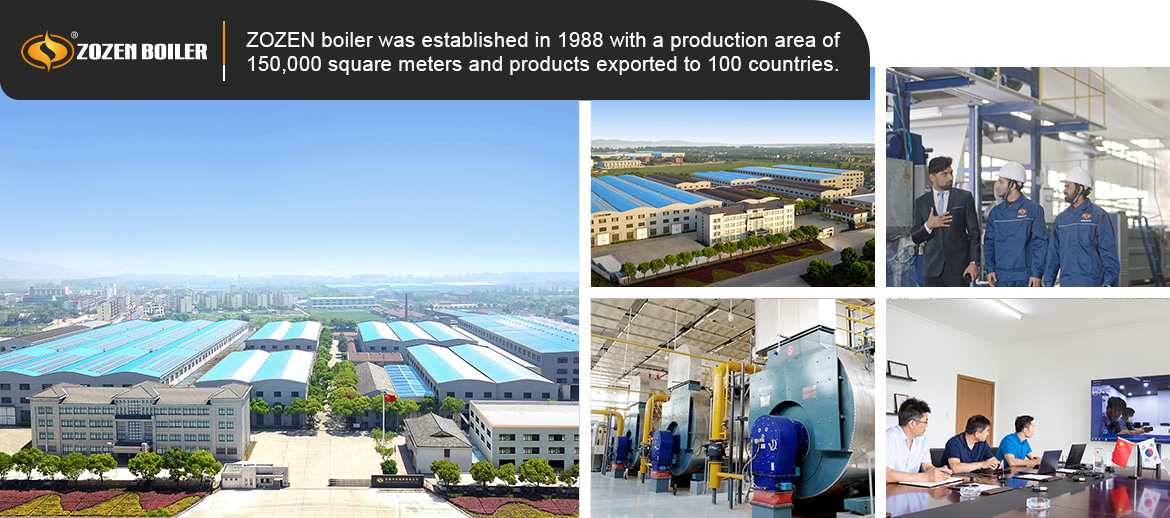

- ABOUT

- CONTACT